Your reliable partner for rapid prototypes & mass production

Advanced Capabilities: Rigid & HDI & Rigid-Flex PCBs

Certified Quality: ISO & UL Compliant

No Minimum Order Quantity

Competitive pricing without sacrificing quality.

PCB Certifications

Quality PCB Solutions Designed to Support Your Projects

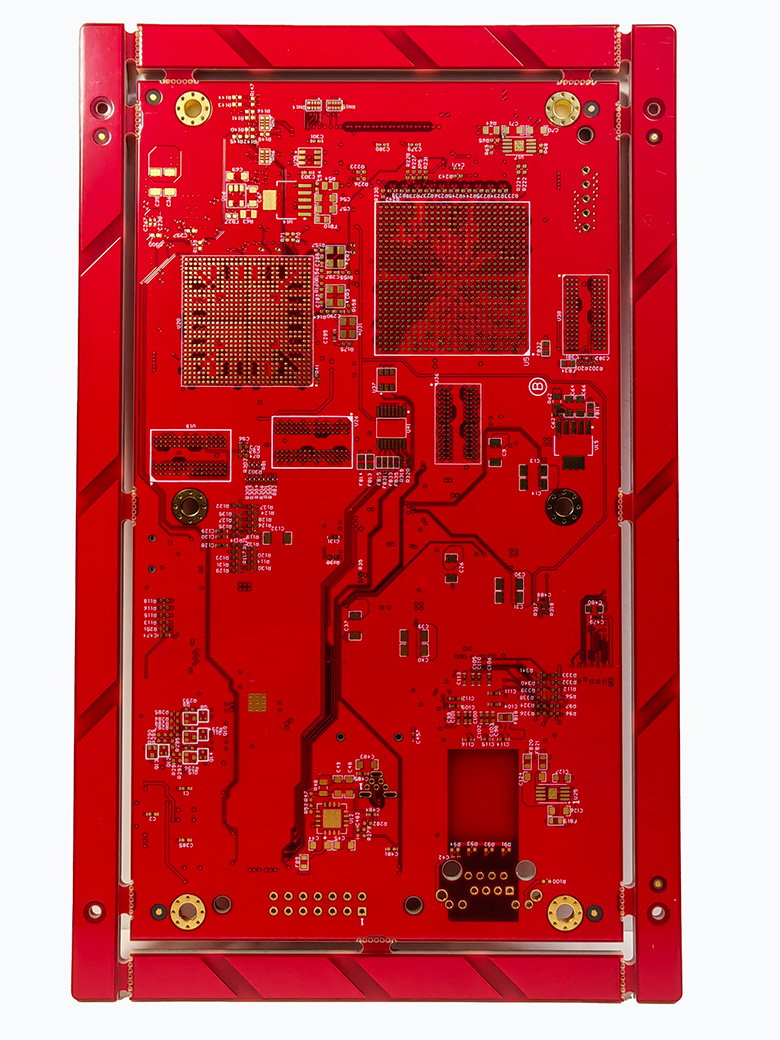

Rigid PCB

- Rigid PCB up to 50Layers

- HDI board with any layer

- Special technology can be available: Half hole, Buried Copper Coin and etc

- Wide Material Options Including High-End RF Laminates: ISOLA 370HR, Rogers 4350, F4BM255

Flex PCB

- Dupont&Panasonic material are available

- Min. Line width/spacing 2/2mil • Stable Bending • Ultra-Thin Builds

- Customized Folded Shape can be supported

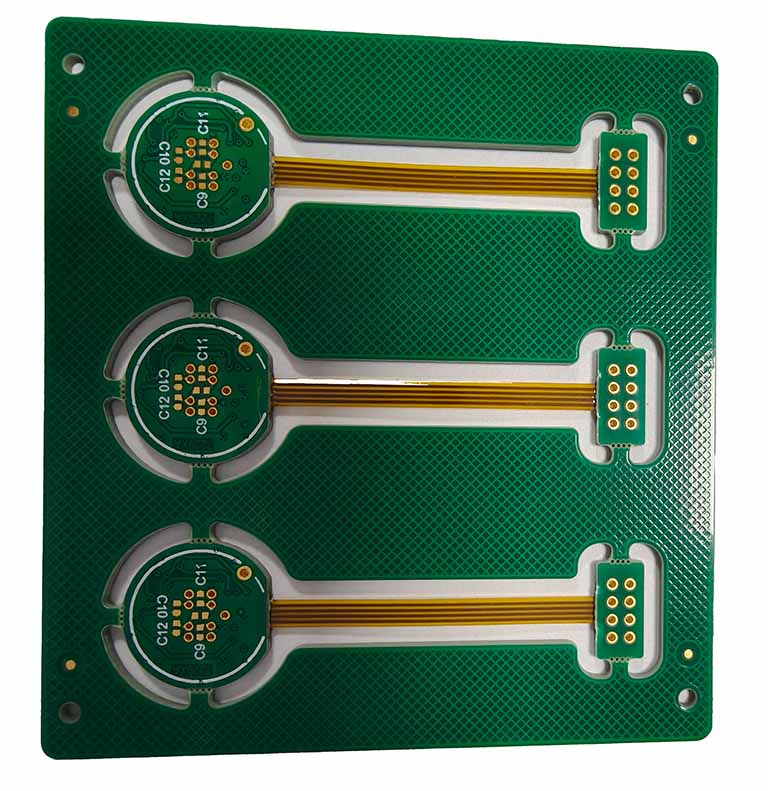

Rigid-Flex PCB

- 10 layer HDI Rigid-flex PCB

- 4Layer Rigid-flex PCB

- 8Layer Rigid-flex PCB with Dupont AP8535R and Arlon 49N

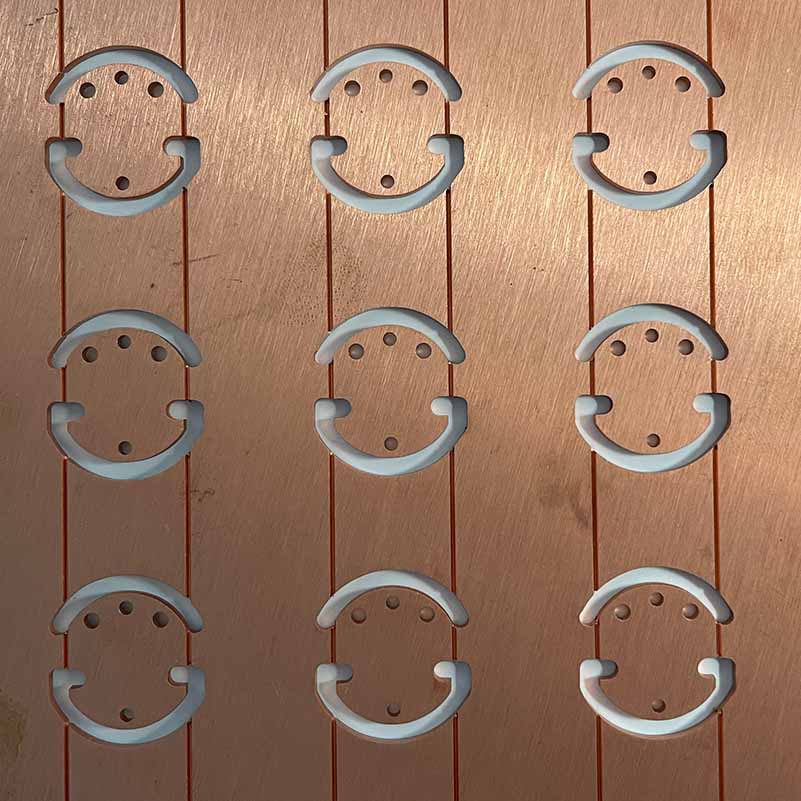

Metal Core PCB

- No MOQ

- Aluminum PCB up to 6L

- Copper PCB up to 4L with True Thermal–Electric Separation

- Depth Milling Counterbore/Countersink(Bell-shaped for better connector fit)

Why Choose Us

HXD Electronics is equipped with advanced automation and precision testing systems, we produce high-quality rigid up to 50layers, rigid-flex and high-frequency, meeting IPC and UL standards.

High-Reliability Standards

We specialize in automotive, industrial, and communication PCBs that require superior performance and durability.Our manufacturing complies with IATF16949,ISO9001,ISO14001 and IPC Class 2 & IPC Class 3 quality standards.

Precision Manufacturing & Full Process Control

From inner-layer imaging to final E-test, every stage is monitored by AOI and SPC systems.

Comprehensive Material Options

We support a full range of laminates including FR4, high-Tg, halogen-free, aluminum-based, Rogers, Taconic, Isola, and Panasonic materials. This enables us to handle high-speed, high-frequency, and thermal management applications with consistent reliability.

Quick-Turn & Low-Volume Flexibility

In the prototype stage, we offer fastest 24-hour prototype service and flexible small-batch production with no minimum order quantity,allowing faster product verification and smoother transition to mass production.

Engineering Collaboration

Our engineering team provides DFM analysis, impedance control support, and material stack-up consulting,helping customers balance performance, reliability, and cost efficiency.

Proven by Industry Leaders

We have long-term partnerships with OEMs and Tier-1 suppliers in automotive, industrial control, and telecom sectors,supplying stable, traceable, and compliant PCB solutions worldwide.

PCB Manufacturing

HXD PCB Fabrication

HXD Electronics is located in Guangzhou,founded in 2005, integrating the full production process — lamination, drilling, plating, imaging, surface treatment, and final testing — all completed in-house for total process control.

Equipped with advanced automation and precision testing systems, we produce high-quality rigid up to 50layers, rigid-flex and high-frequency, meeting IPC and UL standards.

With professional engineering support, stable supply chain, and efficient workflow, we ensure fast lead times and high reliability for demanding applications in all kinds of industries.

PCB Capabilitis

| Layer | 1-50 Layer |

| Board Types | rigid / Flex-Rigid/ Flex/ HDI |

| Board Thickness | 0.2-1.0MM |

| Copper Thickness | 1/2-20 OZ |

| Surface Finish | OSP/LF HAL/ENIG |

| Board Size | 1500*500MM |

| Solder Mask | Green/Black/Blue/White/Red |

| Silkscreen | White/Black/Blue/Yellow |

LDI Exposure

Innerlayer Laminating

Semi-Auto Legend Printing

E-test

Etching

FQC

Frequently Asked Questions

What is the difference between single and double layer PCBs?

A single layer PCB has copper on only one side, while a double layer PCB has copper on both sides, allowing more complex circuits.

What is the maximum size for a single layer PCB?

Up to 600mm × 1200mm depending on material.

What’s the minimum order quantity (MOQ)?

We support prototype orders starting from 1 piece.

Can you provide PCB assembly service?

Yes, we offer turnkey PCB assembly with components sourcing.